China Apple Washing Machine Supplier – Best quality China Industrial Vegetable Blanching Machine Blancher for Food Process – Winlee

China Apple Washing Machine Supplier – Best quality China Industrial Vegetable Blanching Machine Blancher for Food Process – Winlee Detail:

We’ve been also focusing on improving upon the stuff management and QC program to make sure that we could hold fantastic gain in the fiercely-competitive enterprise for Best quality China Industrial Vegetable Blanching Machine Blancher for Food Process, Thanks for taking your worthwhile time to visit us and sit up for have a nice cooperation along with you.

We’ve been also focusing on improving upon the stuff management and QC program to make sure that we could hold fantastic gain in the fiercely-competitive enterprise for Blanching Machine, China Blancher, To win customers’ confidence, Best Source has set up a strong sales and after-sales team to supply the best product and service. Best Source abides by the idea of “Grow with customer” and philosophy of “Customer-oriented” to achieve cooperation of mutual trust and benefit. Best Source will always stand ready to cooperate with you. Let’s grow together!

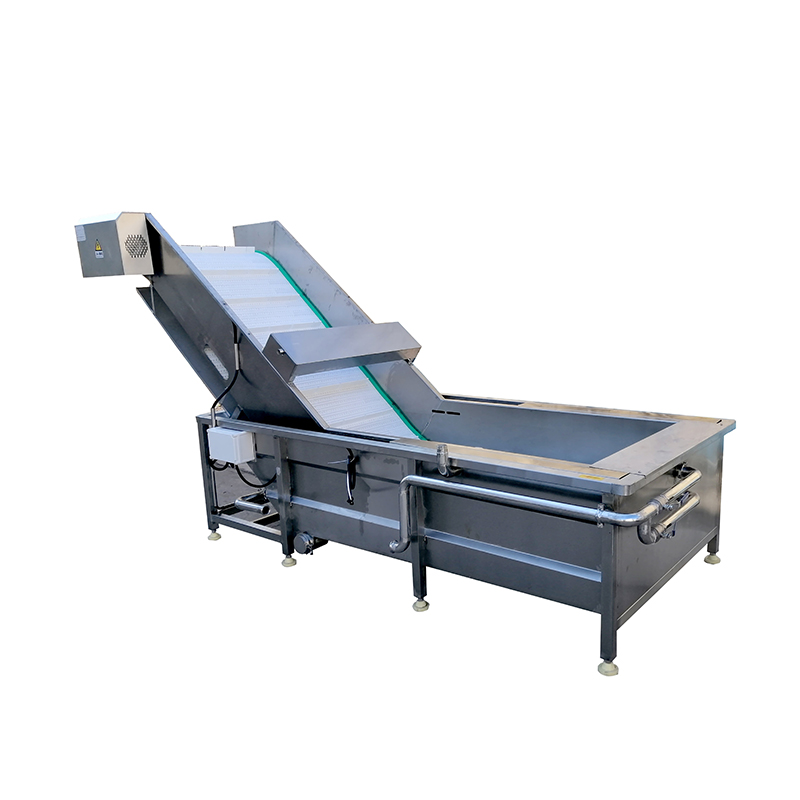

Applicable scope

Blanching and cooking machine is suitable for blanching fruit and vegetable such as mango, lotus root, potatoes, peach, carrots, onion, kelp, etc, cooking meat and seafood such as beef, pork, chicken, burger meat,fish, shrimp and so on.

Machine advantage

1. The equipment using 304 GB food special stainless steel,it is convenient to clean, meet the relevant provisions of the state on food hygiene;

2. Install temperature sensors at the entrance and exit to ensure small temperature error.

3. The tank of equipment is made of 3mm stainless steel; stress point is made of 4mm stainless steel; frame body is made of 50 × 50 × 3 stainless steel tube, insulation outsourcing is made of 1mm stainless steel; the upper cover is made of 1.5mm stainless steel; the bearing and the bearing seat of equipment are all made of stainless steel;

4. There is a filtering system (using the triangular mesh filter) in front of circulating pump to prevent pump impurities into pump and circulate in sterilization tank (cooling tank) too much time; filter cleaning port with no tool disassembly, cleaning impurity is simple and convenient. There is a valve in front of the filter and behind of circulating pump respectively to prevent the waste of water resources in the process of filter cleaning and maintenance of the circulating pump.

5. The stainless steel chain plate speed reducer transmission system: there is equipped the driving motor in the middle of equipment, the front and back gear motor using conveying mode of pulling and getting back, front and back sides of mesh belt synchronously operate to ensure that there is no deviation and tension reduced due to long time unilateral stress,so as to increase the service life of the stainless steel chain plate

6. Using the steam control valves to ensure the timely supply of steam and control the air inlet amount automatically according to the temperature.

7. The thickness of unique insulation layer is 50mm thick, foamed design.

8. Using the Frequency converter to adjust conveyor stepping speed, so it has high accuracy.

9. Using the sprocket chain to turn in the corner of the chain for reducing equipment chain tension.

10. The overall lifting function of equipment belt to facilitate cleaning belt and clean the cooking area.

11.The equipment is equipped with circulating water tank for circulation and oil removal; equipped with automatic water replenishment and filtration device.

Pasteurizer technical parameter

| Cooking time( min) | 10-40 | Cooking temperature | 65-98℃, adjustable |

| Width of conveyor (mm) | 1000-1500 | Running speed | frequency control |

| Voltage | 380v/50HZ (or customized) | Power(Steam heating) | Conveyor motor: 3kw |

| Circulating water pump: 4kw, air pump: 2.2KW | |||

| Steam pressure | 0.3MPa | Capacity(kg/h) | 1000-3000 |

| Dimension(mm) | 6000*1500*1650, 8000*1500*1650, 10000*1500*1650 or 12000*2200*1650 (according to your capacity and cooking time) | ||

We’ve been also focusing on improving upon the blancher quality and stablity to make sure that we could hold fantastic gain in the fiercely-competitive enterprise for Best quality China Industrial Vegetable Blanching Machine Blancher for Food Process, Thanks for taking your worthwhile time to visit us and sit up for have a nice cooperation along with you.

Best quality China Blancher, Blanching Machine, To win customers’ confidence, Best Source has set up a strong sales and after-sales team to supply the best product and service. Best Source abides by the idea of “Grow with customer” and philosophy of “Customer-oriented” to achieve cooperation of mutual trust and benefit. Best Source will always stand ready to cooperate with you. Let’s grow together!

Product detail pictures:

Related Product Guide:

"Quality initial, Honesty as base, Sincere support and mutual profit" is our idea, so as to build repeatedly and pursue the excellence for China Apple Washing Machine Supplier – Best quality China Industrial Vegetable Blanching Machine Blancher for Food Process – Winlee , The product will supply to all over the world, such as: Norway, Swiss, Korea, Corporate goal: Customers' satisfaction is our goal, and sincerely hope to establish long-terms stable cooperative relations with customers to jointly develop the market. Building brilliant tomorrow together!Our company regards "reasonable prices, efficient production time and good after-sales service" as our tenet. We hope to cooperate with more customers for mutual development and benefits. We welcome potential buyers to contact us.

1, Machines are suitable for packaged food, fruits and vegetables, meat products, seafood, fruits and vegetables, bottled drinks and other processing industries.

2, Machines are made of SUS304 stainless steel, have the advantage strong and durable, safe and sanitary.

3, Machines aim to save energy, increase production capacity and reduce user production costs.

4, Machines are customized products, and the heating source is generally steam heating(refers to the pasteurization machine, cooking machine, box washing machine, meat thawing machine), electric heating can be used in special cases.

This company has the idea of "better quality, lower processing costs, prices are more reasonable", so they have competitive product quality and price, that's the main reason we chose to cooperate.