Bath Pasteurizer Suppliers – Bag Jelly and juice pasteurization machine – Winlee

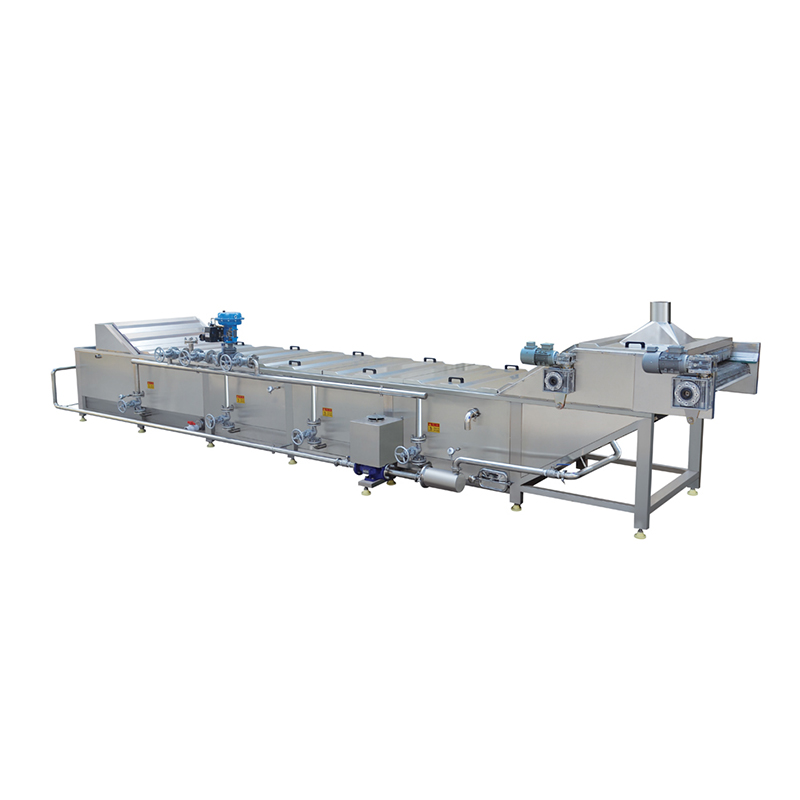

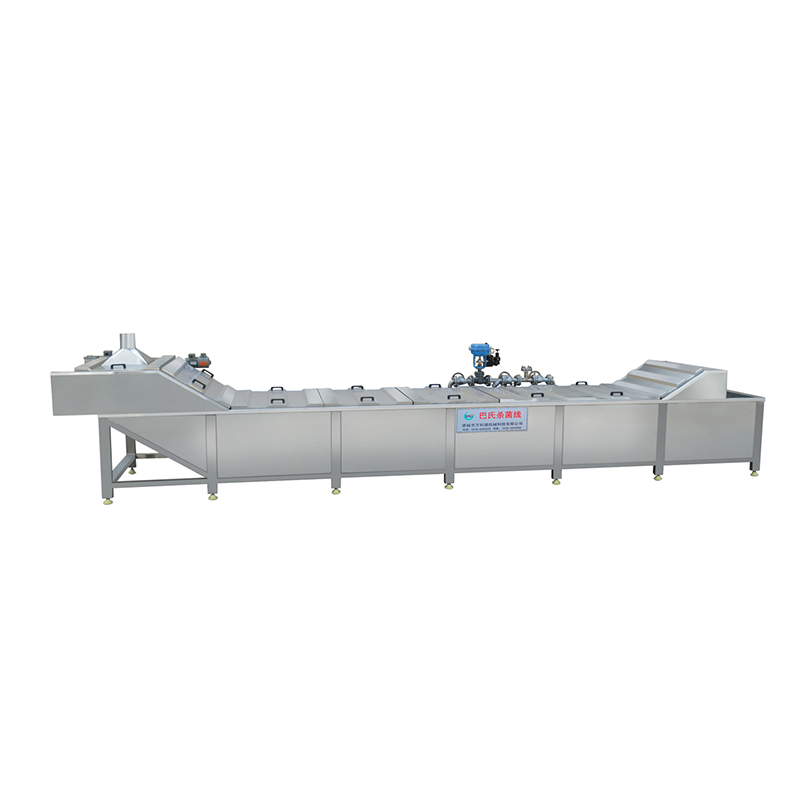

Bath Pasteurizer Suppliers – Bag Jelly and juice pasteurization machine – Winlee Detail:

Applicable scope

Water bath pasteurizer is suitable for packed jelly, fruit and vegetable jam, mustard, pickled cabbage, canned food, condiments, meat and poultry with packages, cans / jars series.

Machine advantage

1. The equipment using 304 GB food special stainless steel,it is convenient to clean, meet the relevant provisions of the state on food hygiene;

2. Install temperature sensors at the entrance and exit to ensure small temperature error.

3. The tank of equipment is made of 3mm stainless steel; stress point is made of 4mm stainless steel; frame body is made of 50 × 50 × 3 stainless steel tube, insulation outsourcing is made of 1mm stainless steel; the upper cover is made of 1.5mm stainless steel; the bearing and the bearing seat of equipment are all made of stainless steel;

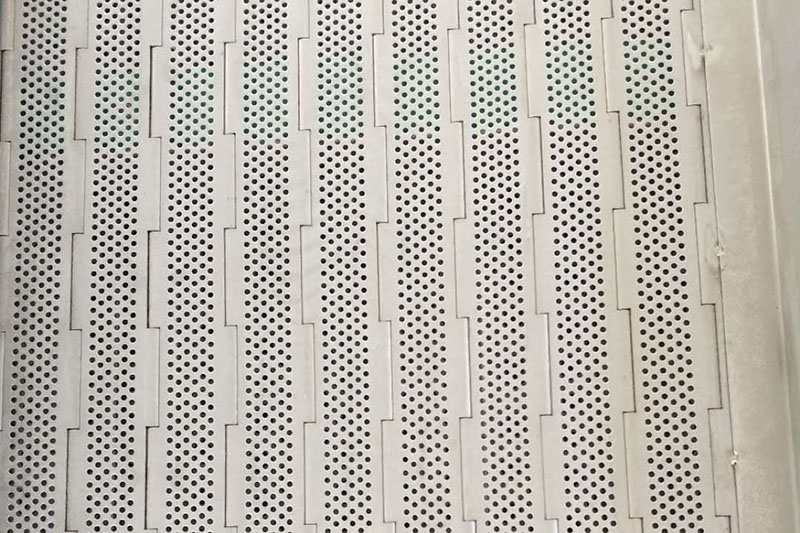

4. There is a filtering system (using the triangular mesh filter) in front of circulating pump to prevent pump impurities into pump and circulate in pasteurizing tank (cooling tank) too much time; filter cleaning port with no tool disassembly, cleaning impurity is simple and convenient. There is a valve in front of the filter and behind of circulating pump respectively to prevent the waste of water resources in the process of filter cleaning and maintenance of the circulating pump.

5. The stainless steel chain plate speed reducer transmission system: there is equipped the driving motor in the middle of equipment, the front and back gear motor using conveying mode of pulling and getting back, front and back sides of mesh belt synchronously operate to ensure that there is no deviation and tension reduced due to long time unilateral stress,so as to increase the service life of the stainless steel chain plate

6. The equipment adopts steam heating, fast heating speed, and uniform water temperature after heating.

7. The thickness of unique insulation layer is 50mm thick, foamed design.

8. Using the Frequency converter to adjust conveyor stepping speed, so it has high accuracy.

9. Using the sprocket chain to turn in the corner of the chain for reducing equipment chain tension.

10. Stainless steel chain plate conveyor(the width is 1000mm), and there are wear design on both sides of conveyor chain plate to prevent products into the chain plate. The steel plate with strong bearing capacity and long service life.

11. Equipment bottom is designed for “Ω” type in order to facilitate cleaning and drainage completely.

![P1UF])XPH7HZIONF~UB@_PA](http://www.wlyfoodmachinery.com/uploads/P1UFXPH7HZIONFUB@_PA.jpg)

12. There is equipped with plurality of cleaning holes at the bottom of equipment , you can use the high-pressure water gun to flush the bottom, it is convenient to clean.

13. The equipment has an independent electric control box, with high degree of automation, equipped with stainless steel shell, it is waterproof and moisture-proof and with long service life.

14. The pasteurizing machine can form a pasteurizing product line with cooling machine, air drying machine and steam drying machine.

Pasteurizer technical parameter

| Pasteurizing time( min) | 10-40 | Pasteurizing temperature | 65-98℃, adjustable |

| Width of conveyor (mm) | 1000-1500 | Running speed | frequency control |

| Voltage | 380v/50HZ (or customized) | Power(Steam heating) | Conveyor motor: 3kw |

| Circulating water pump: 4kw, air pump: 2.2KW | |||

| Steam pressure | 0.3MPa | Capacity(kg/h) | 1000-3000 |

| Dimension(mm) | 5000*1500*1650, 8000*1500*1650, 10000*1500*1650 or 12000*2200*1650 (according to your capacity and pasteurizing time) | ||

Product detail pictures:

Related Product Guide:

We've one of the most innovative manufacturing devices, experienced and qualified engineers and workers, recognized good quality handle systems and also a friendly experienced income team pre/after-sales support for Bath Pasteurizer Suppliers – Bag Jelly and juice pasteurization machine – Winlee , The product will supply to all over the world, such as: St. Petersburg, Tunisia, Salt Lake City, Our Company has professional engineers and technical staff to answer your questions about maintenance problems, some common failure. Our product quality assurance, price concessions, any questions about the products, Please feel free to contact us.

1, Machines are suitable for packaged food, fruits and vegetables, meat products, seafood, fruits and vegetables, bottled drinks and other processing industries.

2, Machines are made of SUS304 stainless steel, have the advantage strong and durable, safe and sanitary.

3, Machines aim to save energy, increase production capacity and reduce user production costs.

4, Machines are customized products, and the heating source is generally steam heating(refers to the pasteurization machine, cooking machine, box washing machine, meat thawing machine), electric heating can be used in special cases.

The sales person is professional and responsible, warm and polite, we had a pleasant conversation and no language barriers on communication.